MODUL cabinets system

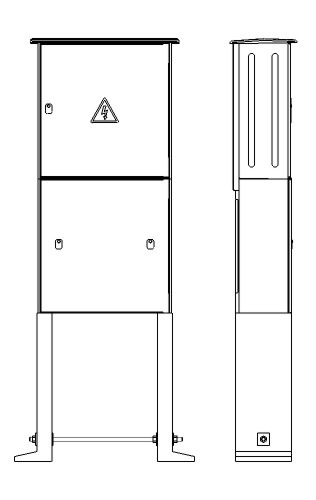

_500_x_242.jpg) Cabinets are solved as a construction set consisting of individual module of 555 mm height, 200 mm depth and 270 mm width. Individual modules are made of plastic SMC material, meeting inflammability requirements V0 a HB40 and adjustment for weather condition and suitable properties for electrical engineering.

Cabinets are solved as a construction set consisting of individual module of 555 mm height, 200 mm depth and 270 mm width. Individual modules are made of plastic SMC material, meeting inflammability requirements V0 a HB40 and adjustment for weather condition and suitable properties for electrical engineering.

Modules can be assembled side by side with or without divider, up to a width of 5 modules what is 1,345 mm. Individual components are designed to be simple to assemble and use to meet a wide range of specific electrical engineering requirements. Modular switchboards can be mounted on a pole, recessed, wall-mounted and placed as a standalone pillar.

Cabinet doors are smooth on the surface, what does not interfere aesthetics of switchgear. Material and door construction eliminate any buckling or bending. Doors are sufficiently resistant to mechanical damage or destruction. Door locking is possible with one or two single locks or one leverage lock system. Door removal is simple and can be done by opening the cabinet. It is possible to install the cabinet ventilation lath without damaging the IP44 coverage.

Sides of the cabinets are lightly fitted with ribs on the outer surface. These ribs make difficult to pull the cabinet out from the masonry. The overall treatment of the sides and dividers secures individual cabinets side by side in an endless series.

Cabinet roof has an overlap across the ground plan of the cabinet. This solution prevents water leaking into the cabinet.

Rear side of the cabinet, which is intended for installation of devices primarily, is supplied with pressed-in M6 or M8.

Assembly procedure for recessed cabinets

Before mounting, door is set down and the recesses dimensions are checked. Plastic cabinets used in masonry are provided with perforations

to prevent cabinets to slip out of the wall.

Using the wooden wedges, cabinet is straightened in such a way that the cabinet protrudes from the masonry with a raised frame (upper and lower part). After the recess has been moistened with water, cabinet is consolidated with cement mortar (or with mounting foam). It is necessary to assure the cabinet dimensions (e.g. wedge it) before the final fixing to avoid cabinet deformation. Cabinet is then cleaned from the cement mortar residues. During supply cables connecting it is recommended to dismount the closing slat (disconnect and connecting cabinets only).

The conductor ends and cables must be insulated, alternatively fitted with terminal crimp or “V” terminal clamps. Conductors are shaped and earthing is connected to clamp (marked with an earthing mark). The cable entry must be sealed to prevent water getting into cabinets. This is ensured by thin layer of cement mortar or possibly walling the entire cabling space up. Ventilation of an IP44 door labyrinth can be improved by air lath (see accessories section).

After the cable assembly, the closing bar is fitted and conductors are marked as necessary. Then the door is fitted and the door closing and locking is tested. Cabinet locks are made with a brass core and greased during production. Further greasing is no longer required.

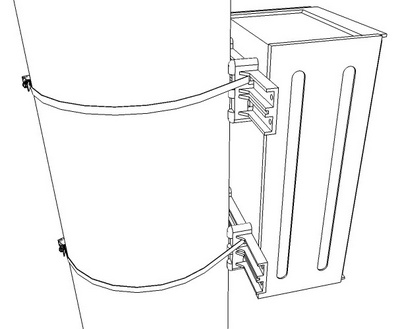

Assembly procedure for pole mount cabinets

Pole mount cabinets are produced for pole mounting and are fully prepared for it. There must be a space for operators in front of cabinet at least 800 mm depth. In case of installation near other distribution devices, safe distance must be kept. Disconnect cabinets are located according to the requirements of distributors.

Pole mount cabinets are produced for pole mounting and are fully prepared for it. There must be a space for operators in front of cabinet at least 800 mm depth. In case of installation near other distribution devices, safe distance must be kept. Disconnect cabinets are located according to the requirements of distributors.

Stabilizers for pole mounting are attached to the rear wall of the cabinets. The "BANDIMEX" system is used to fasten the cabinet to the pole.

Grommets for conductor entry/exit must be cut with a sharp device in the pre-pressed groove (and chosen diameter (50, 63, 76 mm)) before installing the protective power plastic pipes. Power plastic pipes bracket base (supplied separately as an accessory) is attached by the straps to the pole, so that the top is approximately 0.5 m below the upper end of the pipes, and the lower to the centre between the cabinet and the upper bracket. For poles over 9 m in length, it is recommended to use three pieces of pipe brackets. Plastic pipes are fixed with a lower end on the grommets of the cabinet and attached to the base of the bracket by a divided part.

Door is removed from the cabinet and the conductors are pulled into the fixed pipes. The conductors are insulated and alternatively fitted with terminal crimp or "V" or "P" terminal clamps. Then the conductors are marked as needed. Before connecting to the grid, outlet pipes are fitted with covering (supplied separately as an accessory).

If the earthing outlet is fitted into the cabinet It must be also protected by a plastic pipe. This pipe is attached to the pole in the same way as the outlet pipes for the conductors outgoing to overhead power line. The brass terminal M8 on the rear outer side of the cabinet is optionally connected to the housing ground (in case that cabinet is equipped with it). Cabinet earthing is connected to the outer rear part on the M8 brass bolt.

The door is fitted and the door closing and locking is tested. Cabinet locks are made with a brass core, and greased during production. Further greasing is no longer required.

Assembly procedure for wall-mounted cabinets

Wall-mounted cabinets are only those where cable entry can be secured. There must be a space for operators in front of cabinet at least 800 mm depth. In case of installation near other distribution devices, safe distance must be kept. Cabinets are installed at least 0.6 m above the terrain.

Door and internal devices are removed from the cabinet and the mounting holes are drilled into the rear wall of the cabinet. The layout and number of holes must be adapted to the interior facilities of the cabinet and to the state and character of wall on which the cabinet is installed. For cabinet fastening common fasteners (plastic anchors, screws) are used. After fastening the cabinet to the wall, all the devices are mounted back.

Entry/exit conductors must be sufficiently protected from mechanical damage. When the conductors are plugged into the cabinet, they must be insulated and alternatively fitted with terminal crimp or "V" or "P" terminal clamps. Then they are plugged in and the conductors are marked as needed.

All the coverings and cabinet doors are mounted back and the door closing and locking is tested. Cabinet locks are made with a brass core and greased during production. Further greasing is no longer required.

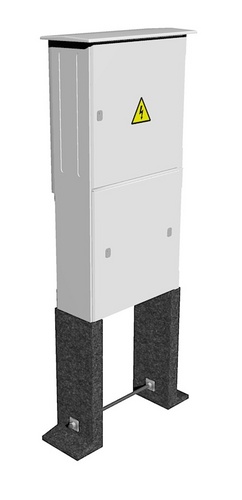

Mounting procedure for standalone pillar cabinets

Standalone pillar cabinets are placed with plinth and a pillar freely in the field or close to the buildings and fences. There must be a space for operators in front of cabinet at least 800 mm depth. In case of installation near other distribution devices, safe distance must be kept. The pillar consists of three basic parts: cabinet, plinth and pillar base. These parts can be ordered as separate items. Cabinet and pillar Type 1 to Type 5 can also be ordered as separate items, but must be prepared as a unit from production. Cabinet can not be rearranged to the pillar.

Standalone pillar cabinets are placed with plinth and a pillar freely in the field or close to the buildings and fences. There must be a space for operators in front of cabinet at least 800 mm depth. In case of installation near other distribution devices, safe distance must be kept. The pillar consists of three basic parts: cabinet, plinth and pillar base. These parts can be ordered as separate items. Cabinet and pillar Type 1 to Type 5 can also be ordered as separate items, but must be prepared as a unit from production. Cabinet can not be rearranged to the pillar.

At first plastic or concrete base of the pillar is assembled. Two base pieces are precisely, according to plinth width spread out with the aid of provided bar brace, so that the pre-drilled holes (countersunk-head bolt) fit tightly in the plinth base holes. Then the base is assembled with a plinth. Set of the plinth and the base of the pillar are placed in the digged hole so that the plinth base is approximately 5 cm below the final terrain level.

The plinth is put straight and ground is added on the sides if needed. If necessary (bearing capacity of the soil is reduced) plinth can be concreted.

Cabinet cover is removed from the plinth by moving two stops toward the plinths axis and opening the cover forwards. Door is removed from the cabinet. Then, locking laths are demounted at the bottom of the cabinet. The cable compartment is equipped with "L" console for cable attachment and also to prevent cables from mechanical stress on the printed circuits. Conductor ends and cables must be insulated, alternatively fitted with terminal crimp or terminal clamps. Conductors are shaped and connected to the clamp (if the clamp is

provided with the cabinet). Then marked as earthing. Grounding conductor is connected there too.

When the cable mounting is completed, we continue with the pillar base covering. We cover the base step by step with inert material. After filling the entire base, locking laths are fixed and conductors are marked as necessary. Then the cover of cable space and cabinet door are placed and the door closing and locking is tested. Cabinet locks are made with a brass core and greased during production. Further greasing is no longer required. Finally, the last terrain adjustments are made.